Message board -

It is widely acknowledged that the manufacturing market is gradually shifting to more practical and cheaper machining methods. In a sense, it seems that plastic injection is the one and only way to meet current trends. Plastic injection molding is better up to satisfy the customers’ demands that cost less and gain more. The benefits that bring to us make it become far more competitive. Moreover, its distinguished strengths like fast production speed, versatility, customization and reliability make it stand out from the crowd.

what is mould in manufacturing process?

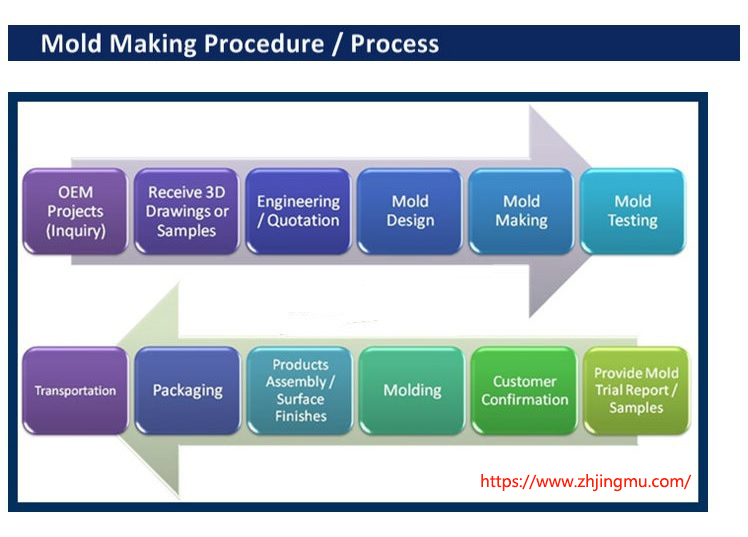

A standard mold manufacturing production/ mold processing should have the following links:

mold marking procedure/process

OEMProjects(inquiry) - Receive3DDrawingsor Samples - Engineering/Quotation - Mold Design - Mold Making - Mold Testing - Provide Mold Trial Report/Samples-Customer Confirmation - Molding - ProductsAssembly/Surface Finishes-Packaging - Transportation

while manufacturing the mold for plastic injection molding, we are supposed to confirm the final design file through analyzing the DFM report and produce a machined part by 3D printing in accordance with the file. Afterwards, move on to next step – make molds for plastic injection molding.

If you take interest in plastic injection molding and desire to learn more, welcome to visit our official website:

Top Injection Molding Companies

How to choose a good mold production manufacturer

product dfm Mold flow analysis