Message board -

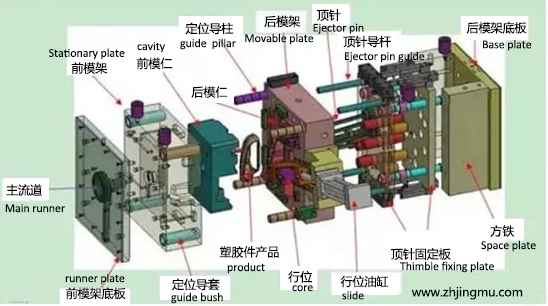

Injection Mold Structure

Without a good mold, there is no way to produce a good injection molded product. The common defects of injection molded parts should first find the cause from the source of the mold. By understanding the common mold defects and solutions, we can reduce defective injection molded products and improve the quality of injection molded parts.

Common mold defects and solutions

一. mold opening and closing, ejector reset, unsmooth action

cause:

1. The guide post and guide sleeve of the mold base do not slide smoothly, and the fit is too tight

2. Inclined top, thimble does not slide smoothly

3. The elastic force or preload of the return spring is insufficient

Adjustment method:

1. Repair or replace the guide post and guide sleeve.

2. Check and repair the inclined top and the thimble

3. Add or replace spring

二. the mold does not match the injection molding machine

cause:

1. The position of the positioning ring is wrong, the size is too large or too small

2. The width of the mold is too large, and the height of the mold is too small

3. The position and size of the ejection hole of the mold are wrong; the position and size of the reset hole are wrongly pulled by force

Adjustment method:

1. Replace the positioning ring and adjust the position and size of the positioning ring

2. Change to a larger tonnage injection molding machine to increase the thickness of the mold

3. Adjust the position and size of the ejector; adjust the position and size of the reset hole

三. difficult to fill parts, difficult to pick up parts

cause:

1. The gating system is blocked, the cross-sectional size of the runner is too small, the gate layout is unreasonable, and the gate size is small

2. The limit stroke of the mold is not enough, the core pulling stroke of the mold is not enough, and the stroke of the mold is not enough

Adjustment method:

1. Check the runners and gates of each section of the gating system, and trim the relevant parts

2. Check whether the strokes of each limit, core pulling and ejector meet the design requirements, and adjust the strokes that do not meet the requirements

四. The mold is transported by water, blocked or leaked

cause:

1. The mold water channel is blocked, and the connection method of the inlet and outlet water pipe joints is wrong

2. Insufficient sealing of water sealing rubber ring and water pipe joint

Adjustment method:

1. Check the connection method of the inlet and outlet water pipe joints of the cooling system and each section of the water channel, and repair the relevant parts

2. Check the water sealing rubber ring and water pipe joints, and repair or replace the relevant parts

In view of the above Common mold defects of various molds, in the next update of the article, we will discuss and share the Common Injection Molding Defects of injection molded parts with the actual case of injection molded parts. Please pay attention to the continuous update of the website: www.zhjingmu.com