Message board -

Jingmu(Zhuhai) Co., Ltd. 30 years of hard work and accumulation of skilled mold design and manufacturing technology:

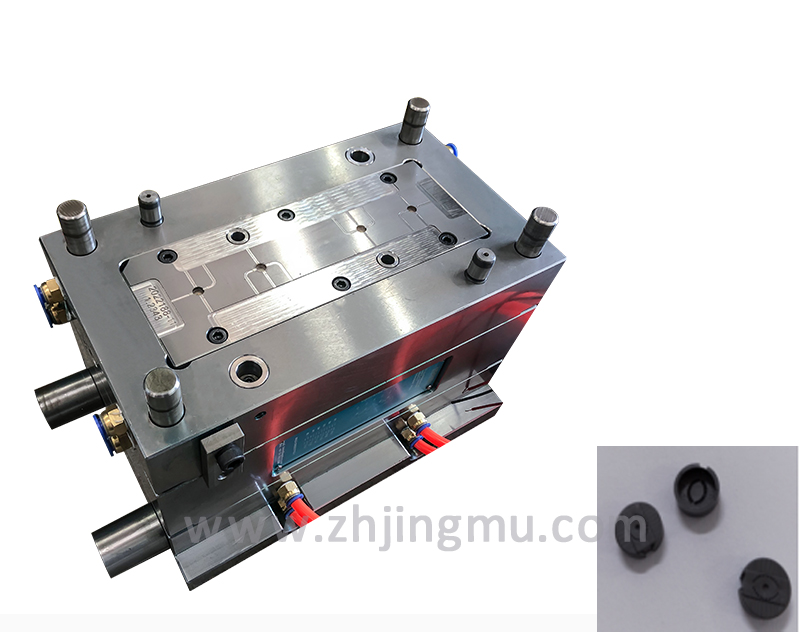

Precision size mold

------------------- precision print head mold, the product is a 0.2mm diameter needle guide hole, 24 fan-shaped arcs are arranged, and the size tolerance is required to be 0.01mm.

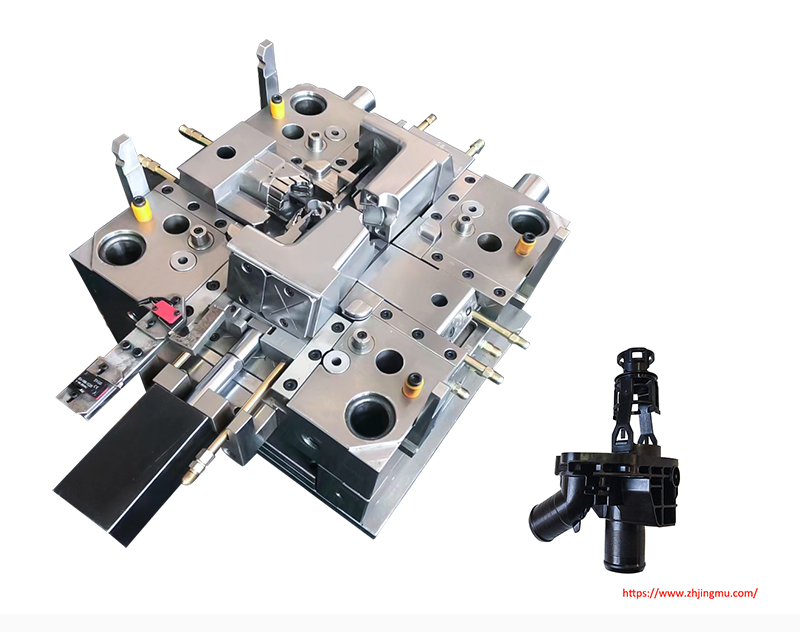

Complicated multi-cavity molds

---------------------Design and manufacture of molds for representative products such as automotive engine thermostat controllers, 4-sided row sliders, and multi-slope products

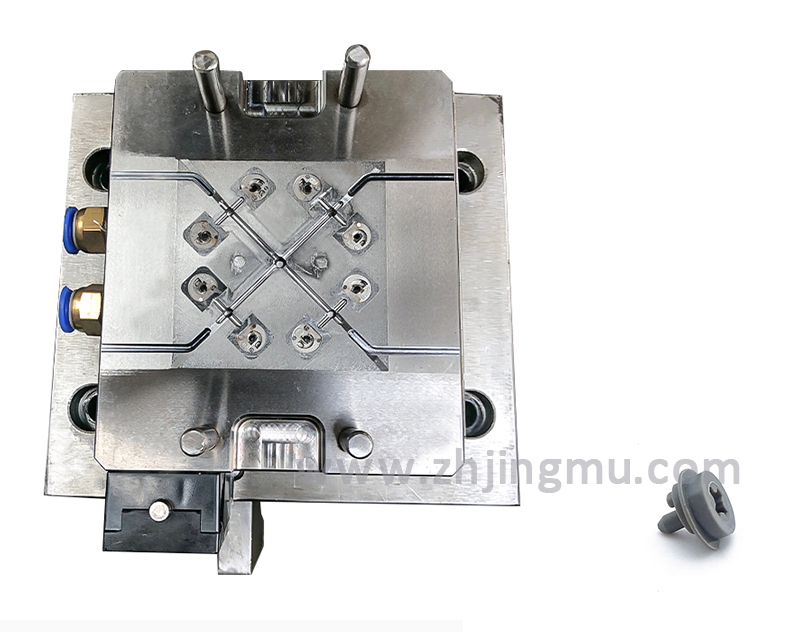

Short-cycle production mold

---------------------the product is a 5mm thick glue position, round, high-flatness deformation control requires a cylinder, the cycle is optimized from 145s to 90s, lean optimized short-cycle mold, and the injection cycle of the multi-cavity mold for micro parts less than 1g is optimized from 20s to 8s.

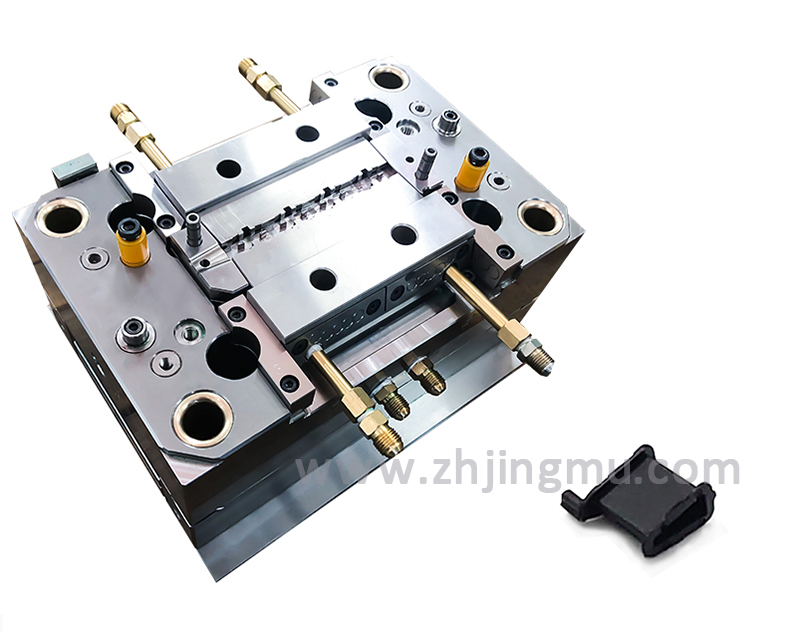

Multi-material (two-color, and encapsulation) complex mold)

---------------------representative products car start key, multiple encapsulation technology for various hardware; medium and low pressure PC and TPV soft rubber two-color multi-row inclined top flip-chip injection molding process mold.

more click :

Plastic mold design and manufacturer