Message board -

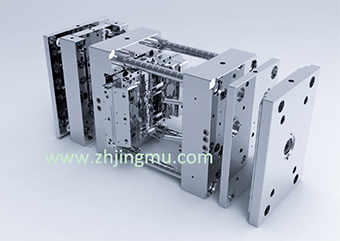

Mold injection molding is a processing method used in the mass production of certain complex-shaped parts. The specific principle refers to: the heated and melted plastic raw material is pushed by the screw of the injection molding machine into the cavity of the plastic mold under high pressure, and after cooling and solidifying, the plastic molding product is obtained.

Common Injection Molding Defects:

1. There are flashes 2. There are missing pieces 3. There are white tops 4. There are scratches 5. Large deformation 6. Large grades 7. Obvious welding

cause:

1. The fit gap is too large

2. The glue is not smooth, and the air is trapped

3. The thimble is too small and the ejection is uneven

4. The slope is too small, there are burrs, and the hardness is not enough:

5. The injection pressure is uneven, and the strength of the product shape is insufficient

6. Processing error

7. Far away from the gate, low mold temperature

Adjustment method:

1. Reasonably adjust the gap and grind the parting surface of the working part

2. Partially add glue and add exhaust

3. Enlarge the thimble and distribute evenly

4. Deburring, ramping, nitriding

5. Trim the gate, the pressure is uniform, and the strength of the product is strengthened

6. Reprocessing

7. Improve the gate and increase the mold temperature

In view of the above Common Injection Molding Defects, in the next article update, we will expand the Common Injection Molding Defects and solutions of injection molded parts with the actual case of injection molded parts. Please pay attention to the continuous update of the website: www.zhjingmu.com

More click:

Injection Mold Structure And Common Mold defects And Solutions

Two-color injection molding technology 2023 high-end exhibition

The 2023 Annual Preferred High-quality Injection Mold Supplier Quality Leader