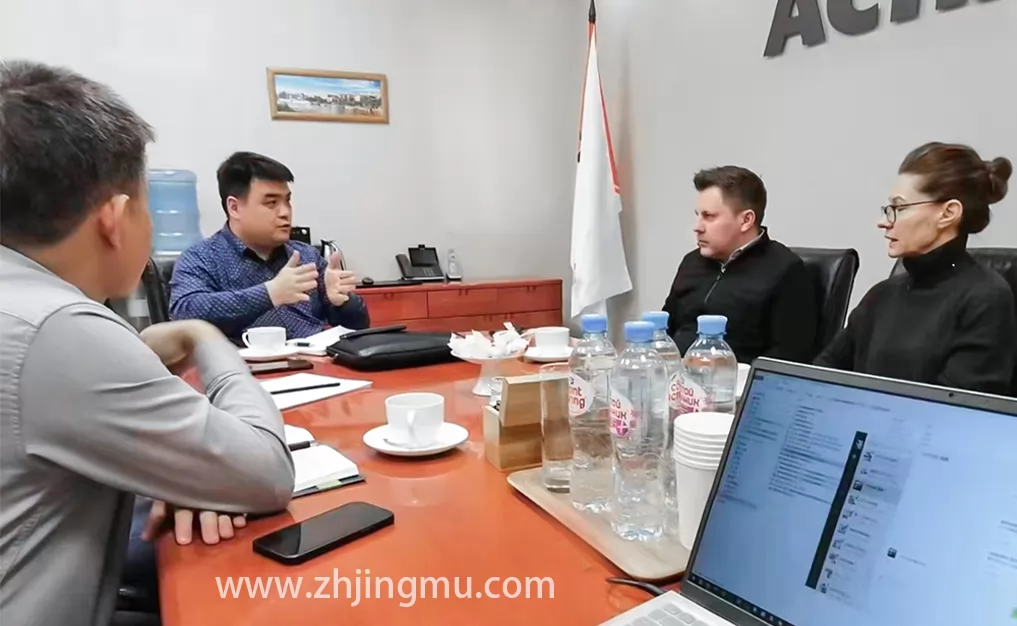

Message board -

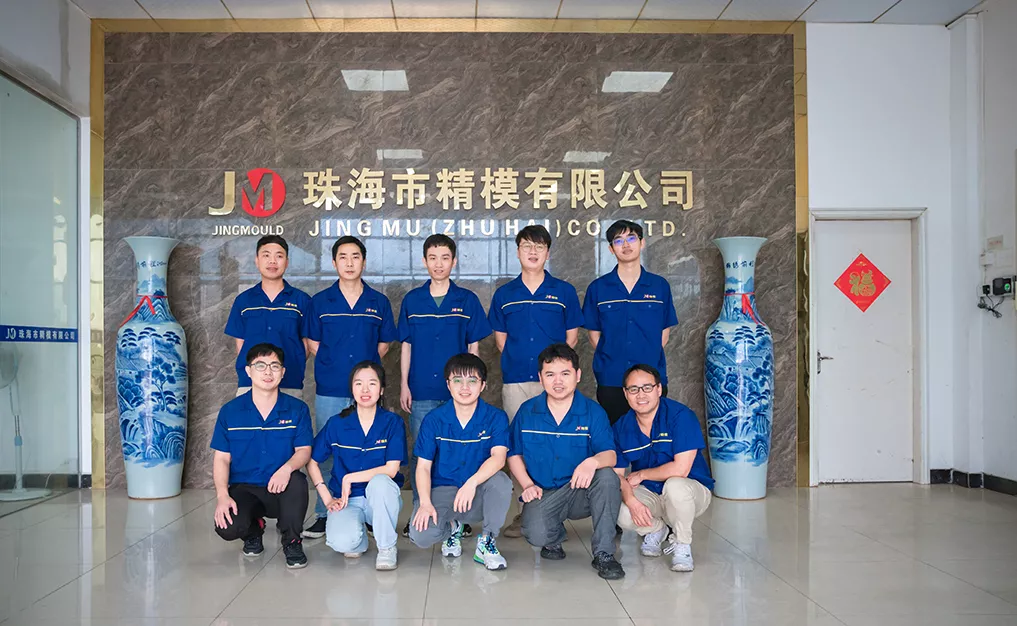

COMPANY PROFILE

30 Years Focus On Mold Opening And Injection Molding Processing

Scale of the new plant:

6500 square metres injection molding and assembly workshop

3000 square metres Mold manufacturing workshop

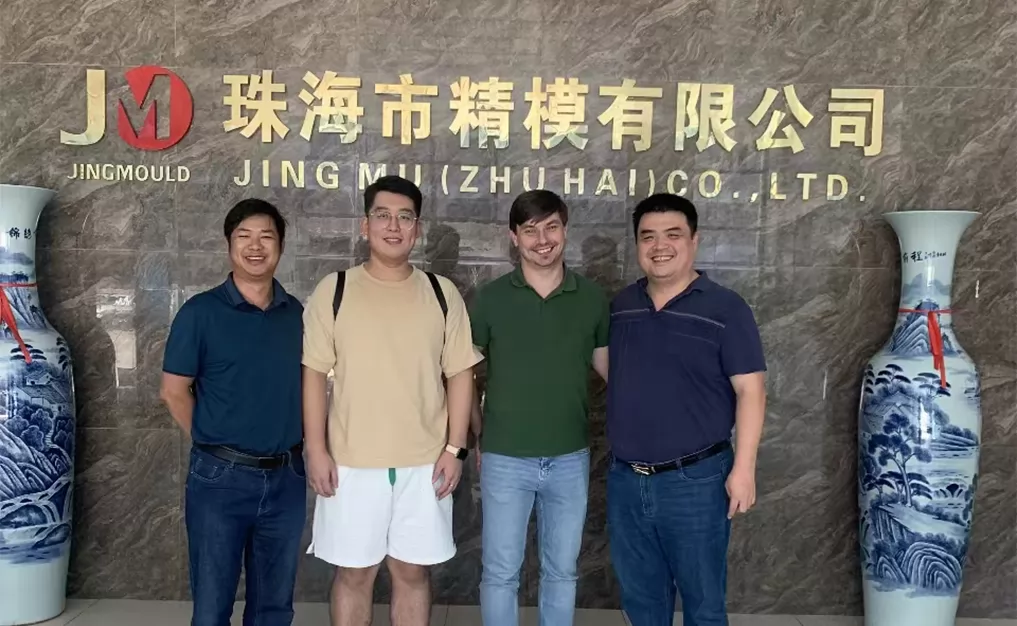

German office was established in 2018.

Jingmu(Zhuhai) Co., Ltd. was established in 1992 in Zhuhai. We have specialized on plastic molds, injection molding and plastic products printing and assembly for more than 32 years, are a manufacturing enterprise integrating research and development, production, sales and service.

Jingmould is a professional manufacturer of injection molds and injection plastics, The industries involved include: electrical appliances, household appliances, household products, communication equipment, gardening and agricultural machinery, automobile and motorcycle accessories, two-color injection molding, precision parts and other injection mold customization source manufacturers. The company's products are exported to the United States, Canada, Brazil, Mexico, Germany, Spain, Italy, Russia, Iran, Japan, South Korea and other countries and regions. There are 26 engineering teams including precision mold project engineers, product engineers, mold design engineers, injection molding process engineers PE, assembly engineers IE, procurement engineers, and quality engineers, responsible for checking and monitoring product technology and quality.

Jingmould has a complete quality control system and has successfully passed ISO 9001; IATF16949; BSCI, multiple technology patents, Ecovadis Silver Enterprise, Specialized Specialty New Small and Medium Enterprises, etc.

Core Advantages

Jingmu(Zhuhai) Co., Ltd was established in 1992 in Zhuhai. We have specialized on plastic molds, injection molding and plastic products...

Why choose us?

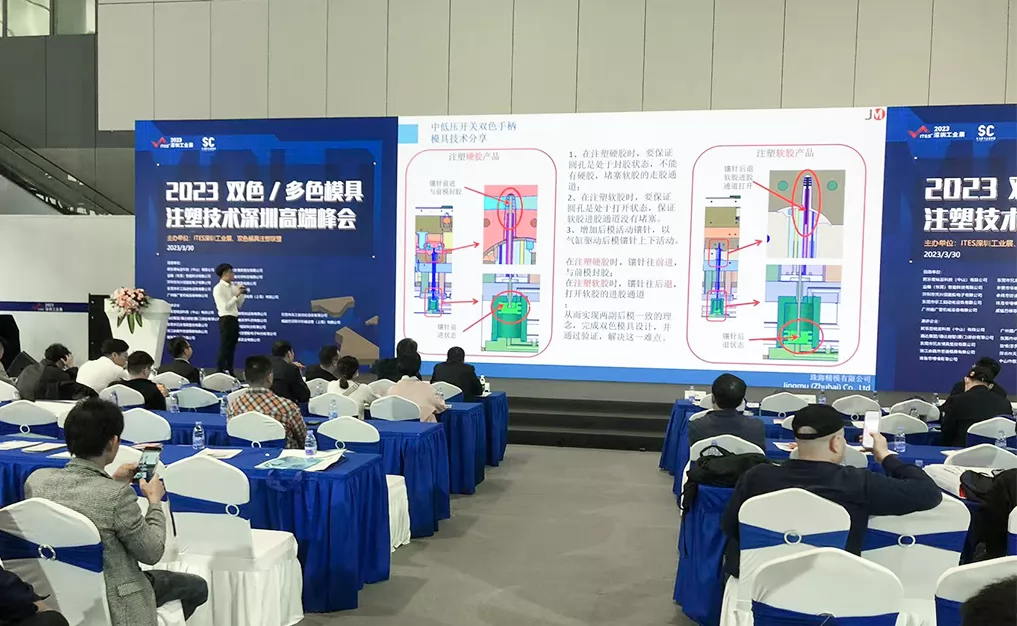

Certificate-level technical strength · Full-process quality control. Because we have more than 30 years of experience in mold manufacturing, and have a long-term experience in manufacturing molds for European and American customers. Regularly participate in various mold technology exhibitions and introduce world-leading advanced equipment. We know that only by striving for perfection can we create low-cost and high-quality products for customers.

How to ensure the delivery time of the mold?

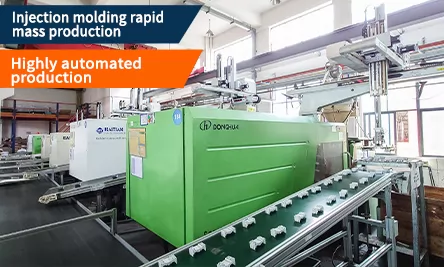

Our company's mold production uses ERP production scheduling system, which can scientifically arrange procurement and production plans according to customer delivery requirements. We have introduced top-level imported equipment to make molds accurate and efficient. We use highly automated production equipment to enable rapid mass production of injection molding.

How to ensure the quality of the mold?

Strict quality inspection process. Before the mold is manufactured, we will fully communicate with customers on various needs, and use mold flow analysis to virtualize the mold injection molding process. Our company has its own "Injection Mold Design Standards", "Mold Quality Standards" and "Mold Process Standards". These standards are based on the needs of various customers and the company's more than 30 years of experience, in order to meet the requirements of mold quality.

I don't know how to communicate with you about the injection mold?

Our two major service spirits: integrity-based, customer first. When the customer does not understand the injection mold but has a demand, we will have professional engineers to serve you, they will listen and answer all your questions patiently, and will provide you with the best solution.

What else can you do?

(1) We can design the product according to the customer's description, and 3D print the designed product as a sample to give the customer an intuitive understanding of the product and perform functional testing.. (2) After the mold is completed, we can provide customers with injection molding production, assembly production, surface treatment and other services.

What should I do if there is a problem with the mold in production?

The mold is guaranteed for 2 years, and we have multiple maintenance points abroad. In China, you can rush to the site for maintenance within 48 hours.

What additional services does the company offer to customers?

From mold design to finished product assembly and mass production, one-stop solution. Possessing ODM service capabilities, multiple mold after-sales maintenance service points, regular on-site customer guidance, together with equipment procurement guidance and services, production line automation\lean production planning.

Mold Equipment

Injection Equipment

Assembly Process

Testing Equipment

Mold Warehouse

mold factory

Makino machine

injection molding plant

injection molding machine

Injection parts inspection machine

Injection molding sample exhibition room

Automatic Injection Molding Machine BOY 25E

ABB Best Quality Award 2024

Congratulations to the company for winning the ABB Best Practice Award in the field of injection molds again

German Injection Mold Exhibition

Zhuhai Jingmu Co., Ltd.

PARTNERS

ENTERPRISE ALBUM